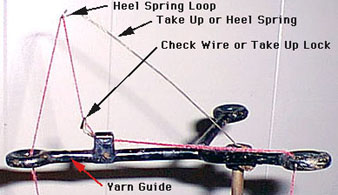

These are the terms used in the Auto Knitter and Gearhart books. There are probably more!

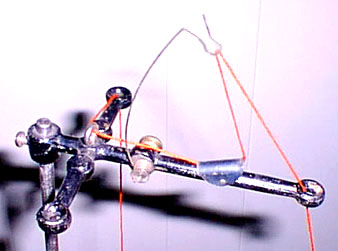

Close-up of Auto Knitter Take Up Lock. They can get bent out of shape, be too rusty to use, or missing. They are pretty soft and can be easily bent. The replacement can be made from coat hangar wire, after you remove the paint.

Another view-----

Notice when the yarn comes out of the hole it goes on top

of the center part of the Take Up Lock against the yarn

guide, and then under the hook end of it. If the center

part of the Take Up Lock does not contact the yarn guide

so it holds the yarn in this position, bend it so it is

parallel with the face of the hole, and located at the

upper edge of the hole.

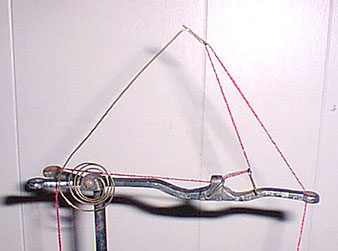

Here is how my Auto Knitter heel spring looks when it is free. This doesn't mean it is right. You should adjust how much tension it has according to what happens when you operate the machine. Too much tension can make the stitches too tight and bog the whole machine down. Gearhart heel springs move to a little past vertical with that weigh arrangement.

This is how I keep my heel spring out of the way when not in use. Move the yarn below the Take Up Lock so it comes out of the hole without restriction. I usually do not run yarn through that little hole when I am making scarves.

What machine does this come from? Does anybody have one like this?

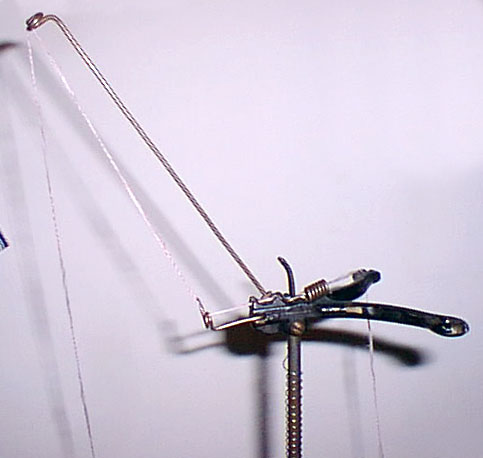

This yarn guide is from an older Gearhart and does not have the weight. The spring is bronze a more common material for springs before 1900. You can still buy bronze spring wire,and it is good because it does not rust. I think this may be a good way to modify the Gearhart instead of repairing that weak solder joint.

| Here is a LeGare Yarn Stand.

This is the full up position when no tension is

on the yarn from below. You would seldom see it

this far up when in use. See more closups of the LeGare yarn stand on next page. |

|